China OEM China Reducer Type Rubber Expansion Joint Flanged DIN / BS / JIS / ANSI / ASA

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for China OEM China Reducer Type Rubber Expansion Joint Flanged DIN / BS / JIS / ANSI / ASA, Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, don’t hesitate to contact us.

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for China Rubber Expansion Joint, Reducer Expansion Joint, With the development and enlargement of mass clients abroad, now we’ve got set up cooperative relationships with many major brands. We have now our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

Details

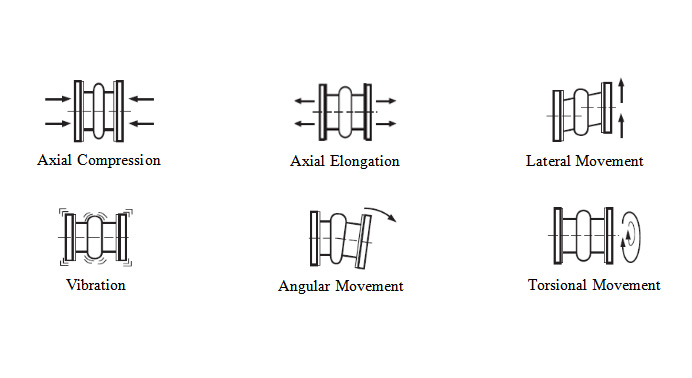

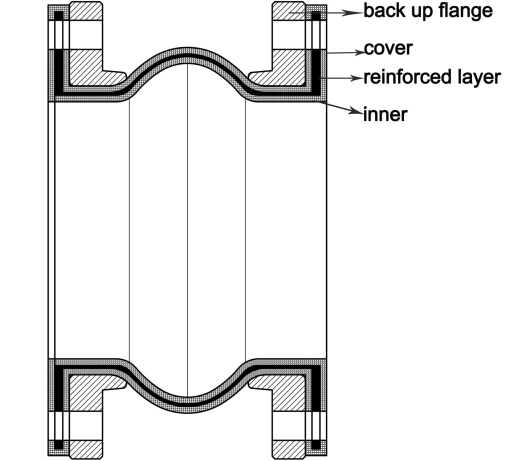

Wide arch system is the molded expansion joint, with integral flange and without a metal reinforcement at the neck of the body. Wide arch allows greater movements and low spring rates comparing to spool type. WA and WAF is used for an economical wide arch rubber expansion joint. WAF is filled arch, with 50% of the WA allowed movements, but it has 4 times spring rates than wide arch.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

WIDE ARCH (WA)-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

|||

|

2″ |

50 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

35° |

150 |

15 |

|

2 1/2″ |

65 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

30° |

150 |

15 |

|

3″ |

80 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

30° |

150 |

15 |

|

4″ |

100 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

25° |

150 |

15 |

|

5″ |

125 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

25° |

150 |

15 |

|

6″ |

150 |

6″ |

1-3/4″ |

3/4″ |

±1″ |

20° |

150 |

15 |

|

8″ |

200 |

6″ |

1-3/4″ |

3/4″ |

±1″ |

20° |

150 |

15 |

|

10″ |

250 |

8″ |

1-3/4″ |

3/4″ |

±1″ |

15° |

150 |

15 |

|

12″ |

300 |

8″ |

1-3/4″ |

3/4″ |

±1″ |

15° |

150 |

15 |

|

14″ |

350 |

8″ |

2″ |

7/8″ |

±1-1/8″ |

12° |

150 |

10 |

|

16″ |

400 |

8″ |

2″ |

7/8″ |

±1-1/8″ |

12° |

150 |

10 |

|

18″ |

450 |

8″ |

2″ |

7/8″ |

±1-1/8″ |

9° |

150 |

10 |

|

20″ |

500 |

8″ |

2″ |

7/8″ |

±1-1/8″ |

9° |

150 |

10 |

|

24″ |

600 |

10″ |

2-1/4″ |

1″ |

±1-1/8″ |

9° |

150 |

10 |

|

WIDE ARCH: FILLED ARCH (WAF)-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

|||

|

2″ |

50 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

17.5° |

150 |

15 |

|

2 1/2″ |

65 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

15° |

150 |

15 |

|

3″ |

80 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

15° |

150 |

15 |

|

4″ |

100 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

12.5° |

150 |

15 |

|

5″ |

125 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

12.5° |

150 |

15 |

|

6″ |

150 |

6″ |

7/8″ |

3/8″ |

±0.50″ |

10° |

150 |

15 |

|

8″ |

200 |

6″ |

7/8″ |

3/8″ |

±0.50″ |

10° |

150 |

15 |

|

10″ |

250 |

8″ |

7/8″ |

3/8″ |

±0.50″ |

7.5° |

150 |

15 |

|

12″ |

300 |

8″ |

7/8″ |

3/8″ |

±0.50″ |

7.5° |

150 |

15 |

|

14″ |

350 |

8″ |

1″ |

7/16″ |

±0.563″ |

6° |

150 |

10 |

|

16″ |

400 |

8″ |

1″ |

7/16″ |

±0.563″ |

6° |

150 |

10 |

|

18″ |

450 |

8″ |

1″ |

7/16″ |

±0.563″ |

4.5° |

150 |

10 |

|

20″ |

500 |

8″ |

1″ |

7/16″ |

±0.563″ |

4.5° |

150 |

10 |

|

24″ |

600 |

10″ |

1.125″ |

1/2″ |

±0.563″ |

4.5° |

150 |

10 |

|

Wide Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Standard O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

130 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

135 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

170 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

205 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

240 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang